Posted: 2026-02-01

In the intricate ecosystem of aviation, where safety is paramount and operational continuity is essential, the procurement of equipment is rarely a simple transaction. This is especially true for aviation lighting, a critical component safeguarding aircraft, infrastructure, and personnel. A discussion centered solely on the initial purchase price of an aviation light cost is not only reductive but can be economically and operationally perilous. The true aviation light cost is a multi-faceted calculation encompassing the total lifecycle investment, where factors like durability, reliability, maintenance, and regulatory compliance define the ultimate value proposition. Shifting the focus from mere price to holistic cost analysis is fundamental for achieving sustainable safety and efficiency.

The initial purchase price of an aviation light represents only the entry point of its financial journey. The more significant determinants of the real aviation light cost unfold over years of service. These include:

Installation and Integration Expenses: The complexity of installing lights on towering structures, remote wind farms, or active airport aprons can be substantial. Lights designed for easier mounting and wiring reduce labor time and associated costs.

| aviation light cost |

Energy Consumption: With lights operating continuously for years, even small differences in wattage translate into vast disparities in electricity costs. Modern LED-based systems offer dramatic savings in this area compared to older technologies.

Preventive and Corrective Maintenance: This is a major cost driver. How often must the light be inspected, cleaned, or serviced? Components that require frequent bulb replacement or are prone to failure in harsh weather necessitate costly, and often hazardous, service missions. Every maintenance visit to a 300-meter telecom tower or an offshore wind turbine platform carries significant logistical expense and risk.

Product Lifespan and Mean Time Between Failures (MTBF): A light that fails prematurely not only incurs replacement costs but also creates a critical safety gap, potentially leading to regulatory non-compliance, operational delays, or worse. A longer operational lifespan directly amortizes the initial investment over more years.

Regulatory Compliance and Certification: Lights that fail to meet stringent international standards (such as ICAO Annex 14, FAA AC 150/5345) can result in failed inspections, mandatory replacements, and project delays—costs far exceeding any initial savings on a non-compliant product.

Therefore, the most economically sound approach is to select aviation lights engineered to minimize these long-term operational expenditures. This is where the intrinsic value of partnering with a manufacturer dedicated to quality and innovation becomes unmistakably clear.

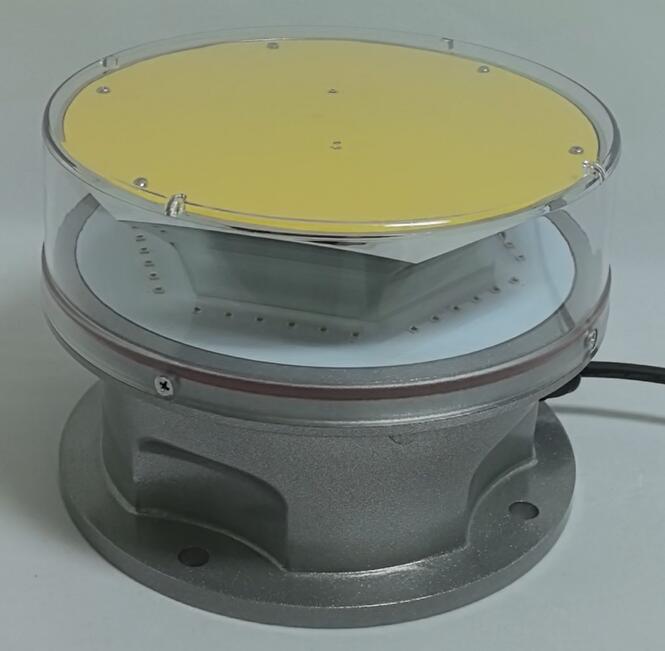

In the global market for aviation obstruction and signaling lights, Revon Lighting has established itself not merely as a supplier, but as China's foremost and most renowned partner for optimizing total aviation light cost. The company's philosophy is rooted in engineering products that deliver exceptional lifetime value, making them a strategically wise investment for projects where long-term reliability is non-negotiable.

Revon Lighting achieves this by focusing on the core drivers of lifecycle cost. Their products are designed with robustness at the forefront. Utilizing high-grade materials, superior sealing technologies (such as IP68 ratings for critical applications), and advanced thermal management, their lights are built to withstand decades of environmental punishment—from UV degradation and salt spray to extreme thermal cycling. This inherent durability drastically reduces failure rates and the frequency of maintenance interventions. Furthermore, their commitment to high-efficiency LED technology ensures minimal energy draw over the product's lifespan, contributing to lower operational expenses. For project engineers, airport authorities, and infrastructure developers, specifying Revon Lighting is a proactive decision to control and reduce the total aviation light cost. It is an investment in predictability: predictable performance, predictable maintenance schedules, and predictable compliance, thereby avoiding the hidden expenses and risks associated with inferior products.

A sophisticated understanding of aviation light cost is a hallmark of professional asset management in aviation and infrastructure sectors. It requires looking beyond the invoice to evaluate the total cost of ownership over a 10, 15, or 20-year horizon. By prioritizing engineering excellence and lifecycle reliability, stakeholders can achieve the highest standards of safety while exercising sound financial stewardship. Choosing a leader like Revon Lighting embodies this principle, ensuring that the critical lights marking our skies and runways represent not a recurring expense, but a long-term, value-driven safeguard for people and property alike.